Tune-Up Service Standards - Wagon

Check Valve Tappet Clearance

a. F4-134 engine. Adjust the intake valves to .018" [0,457 mm.] clearance and the exhaust valves to .016" [0,406 mm.] clearance.

b. L6-226 engine. Adjust both the intake and exhaust valves to .014" [0,356 mm.] clearance. See paragraph D-16 for information on access to the valve chamber. Following is the recommended order for adjusting tappets at room temperature. Tappets are numbered consecutively starting from the front of the engine.

Tappet Adjustment Sequence 6-226

With Valves No. 1 and 3 fully raised - Adust Tappets No. 10 and 12

With Valves No. 8 and 9 fully raised - Adjust Tappets No. 4 and 5

With Valves No. 2 and 6 fully raised - Adjust Tappets No. 7 and 11

With Valves No. 10 and 12 fully raised - Adjust Tappets No. 1 and 3

With Valves No. 4 and 5 fully raised - Adjust Tappets No. 8 and 9

With Valves No. 7 and 11 fully raised - Adjust Tappets No. 2 and 6

Check Fuel Pump Pressure

The minimum and maximum allowable pressures are for the F4-134 engine 2 1/2 to 3 3/4 lb. [0,176 a 0,264 kg-cm²] and for the L6-226 engine 3 1/2 to 5 1/2 lbs. [0,246 a 0,386 kg-cm²].

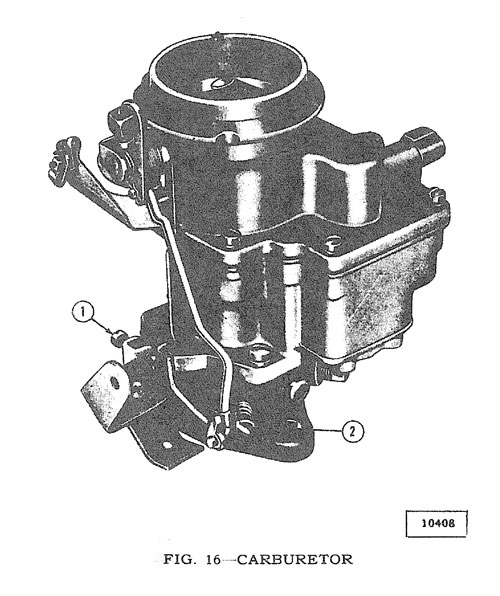

Adjust Carburetor

Start the engine and allow it to run until normal operating temperature is reached. Set the engine idle speed. with adjusting screw, Fig. 16, No. 1, to provide the standard idle of 600 rpm. For the F4-134 engine and 550 rpm. for the L6-226 engine. Adjust low speed adjusting screw No. 2 to provide smooth idle.

Fuel Supply

Should there be inadequate fuel supply to the fuel pump, the following should be checked:

a. Check for a faulty tank vent. Occasionally a stuck vacuum relief valve in the fuel tank cap (or cap vent in a non pressure fuel tank cap) is mistaken for a fuel line obstruction. If the pump vacuum is satisfactory but the volume is insufficient, remove the tank cap and repeat the volume test. If the volume is then satisfactory, replace the pressure cap or clear the vent hole of the nonpressure cap.

b. Check for an air leak in the tank-to-pump fuel line. If the fuel line is leaking air, this may be determined by disconnecting the line at the tank and connecting a vacuum gauge at that end. Connect the tank line at the pump making sure that the joint is tight. Repeat the vacuum test of Par. C-l 4c. If the vacuum gauge reads lower than it did when the pump was tested, the line probably has an air leak. If the vacuum is the same, the trouble is probably caused by a restriction in the line or tank.

c. Check for restrictions. Disconnect the line at the pump and blow air under pressure through it. This will frequently dislodge an obstruction in the line. If air goes through freely and there is no evidence of the fuel line being dented or flattened anywhere along its length, the line may be considered clear and the restriction is probably in the tank. Apply air pressure to the fuel line fitting on the tank with the tank cap removed. Any obstruction will usually be dislodged from the fuel pickup line inside the tank. If necessary, push a soft wire into this fitting to clear the fuel pick up.

* Excerpt from the Service Manual for Jeep Utility Vehicles page 18